Design

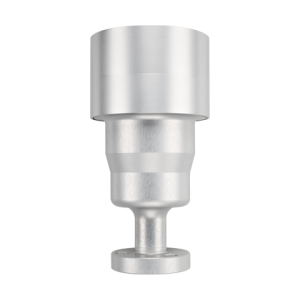

The PSP-400 consists of the following principal components:

- Strong aluminum alloy enclosure

- Polysilicon pressure sensor with self-diagnostic capability

- Evaluation unit with microprocessor

- Relays with floating contacts for signaling limit violations

- LED status display

- Plug-in connectors (Phoenix Combicon)

- RJ-45 data output

- Aluminum alloy pressure connection

Operating principle

Before the device is put into service, the desired hydraulic limits are set with a PC or notebook computer. During operation the polysilicon sensor of the PSP-400 continuously measures the hydraulic pressure in the connected system. The current measured values are output by way of the RJ-45 interface. Limit violations activate the floating NC/NO contacts (relays) and trigger the relevant signal. In addition, LEDs on the unit display the current status (green LED: normal operation, red LED: limit violation). The output measured values and signals facilitate precise control of the hydraulic pump and the reliable activation of lockouts and alarms in case of a malfunction.

Benefits

High operating reliability is ensured by the sensor’s self-diagnostic capability and an additional relay for error messages. The set limit values are retained even in the event of a power failure. The electronic pressure switch is designed for a service life of > 30 years. It is impossible for an undefined condition to arise at the relay outputs in case of a malfunction of the sensor, evaluation unit (microprocessor, memory, A/D converter, DC-DC converter etc.), or output device (relays). Apart from monitoring the hydraulic operating mechanisms of high-voltage circuit breakers, the PSP-400 is also suitable for other hydraulic pressure applications.

The information on this website represents the state of knowledge at the time of writing. Technical specifications are subject to modifications. Comde-Derenda GmbH accepts no liability whatsoever for the content provided or for damages resulting from the use of its products.